LCB710 – An engineer's dream

Controlling a large current with a small one without a physical connection

Controlling a large current with a small one without a physical connection, traditionally leads to a knee-jerk reaction of relays. Optocouplers traditionally were limited to low currents.

For quite a bit of time, solid-state relays have been on the market. What once was a relatively large and expensive component is now available in comfortable six pin surface mount ICs – one example, which would have cost a lot a few years ago, is shown in the box below:

First of all, most solid-state relays, that includes the LCB710, are based on the principle of the optocoupler. This means that a small control current lights an LED, which then emits photons which trigger a set of photo transistors.

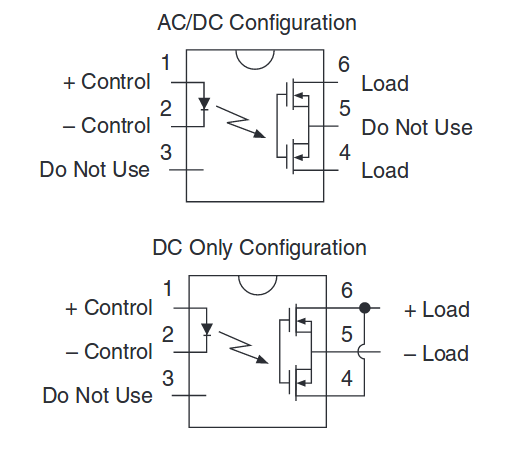

In the case of our part, the internal structure – as shown in the product data sheet – looks like this:

Very flexible

One strength of traditional relays was that they did not give much of a fuss about what signal they were handling: once the switch was closed it – essentially – carried whatever you chased along it. Solid-state relays were problematic in this regard, as many of them could conduct current only in one direction. Fortunately, the component at hand does not have this problem.

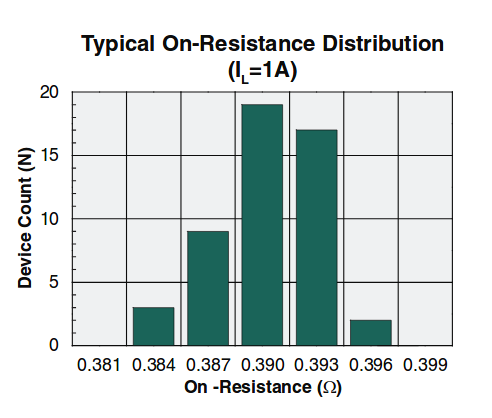

Furthermore, the turn-on resistance is quite acceptable, with an average range of like 0.5 ohms. Forgive yours truly for reprinting the datasheet here – the following things are very very cool:

Printing standard deviations in a datasheet is a surefire way to endear your product to this reviewer

One key benefit of solid state relays is their quick turn on time: in principle, you can expect turn-off in less than 2 ms, while activation is done about 0.75 ms in the worst case – in both cases, expect the majority of the parts to do significantly better, which can be seen as an invitation to select components by hand.

Finally, also keep in mind that performance is quite satisfactory: current of up to 1A can be controlled with 2mA. The galvanic insulation barrier is quite beefy, being able withstand to 3750 V RMS.

To select, or not to select?

An unverified rumour circulating in Eastern Europe claims that one of the reasons why Solartron went awry was their expensive selection process. Selecting parts provides a way to drive additional revenue to your company: selling prepared replacement parts is fun.

However, be careful; you need to hold additional stock and have quite a bit of labour costs. If you can design around it, to so by all means…especially as parts also change as they age.