TT Electronics ULW3-100RJA1 – A Resistor Which Doubles as a Fuse

In many cases, a resistor is found in series with a fuse. If an assembly is intended to be factory-maintained only, fusible resistors let you eliminate one of the components.

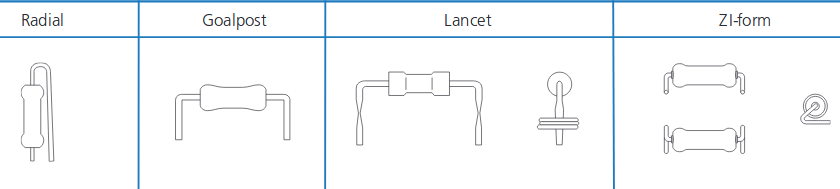

Fusible resistors usually come in device families. We will focus our attention on the ULW3-100RJA1 – it is a 100 Ohm through-hole resistor with a rated power of 3 watts. A variety of lead options are offered, as is shown in figure one.

TT Electronics offer their fusible resistors in various lead configurations

Through-hole parts may increase assembly costs, but are beneficial for repair – if your technicians are instructed to cut the leads before desoldering the part, minimal amount of heat stress is to be expected inside of the PCB. Due to the high levels of heat reached during “shutdown”, PCBs should be of high quality – if the PCB catches fire, the fuse failed its function.

Fusible resistors, generally, are slower than dedicated fuses. In the case of our part, a five second overload of 15 watts is considered allowed – the circuit needs to be able to withstand significant overcurrent if a fusible is to be the only protective element used.

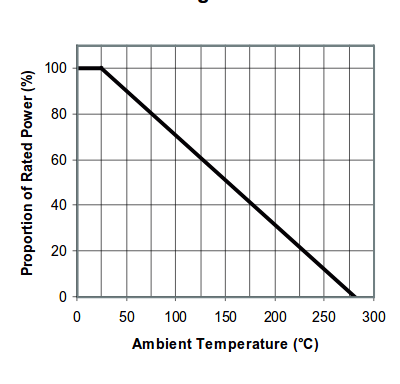

Finally, keep in mind that ambient temperature directly affects the switching voltage levels. Figure two, taken from the datasheet, shows that the rated power starts to fall at about 25 degrees celsius.

Ambient temperature has significant impact on current levels.

TT Electronics obeys the UL1412 standard, which can be considered the go-to set of rules for fusible resistors – visit https://standardscatalog.ul.com/standards/en/standard_1412_5 to find additional information not found in the datasheet.