Vishay’s CRCW-HP e3 Family & the CRCW120647R0FKEAHP

Spikes are the bane of any and every automotive design. In many cases, they kill resistors by temporary terminal overload. Vishay’s CRCW-HP e3 family, one of which is the CRCW120647R0FKEAHP, provides designers with the tool to combat the problem.

In theory, short-term overloads should not be a problem for resistors - after the spike has gone away, the thermal capacity of the part should ensure that the total heat remains in a manageable range. Sadly, this is not the case in practice - local thermal maxima can make the part burn out either immediately or as time goes by.

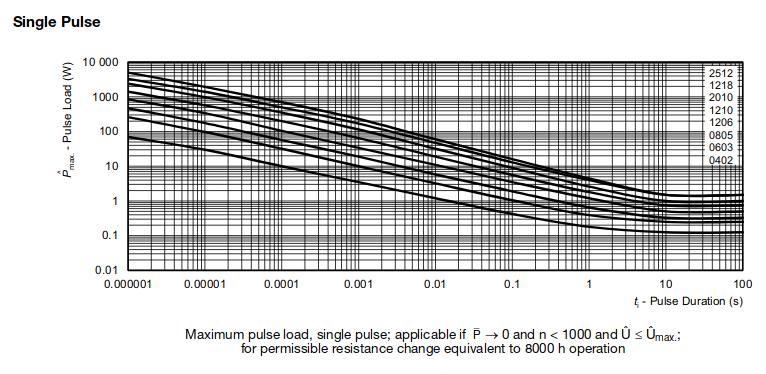

Vishay’s CRCW-HP e3 family uses a ceramic substrate which is intended to provide for a more robust thermal behavior due to its ability to spread heat quickly. This means that the parts are pretty robust when it comes to dealing with spikes. Our figure, taken from the data sheet, shows how the parts handle loads as long as the amount of time which they are subjected to them remains short.

Spike duration, obviously, influences the behaviour of the CRCW120647R0FKEAHP

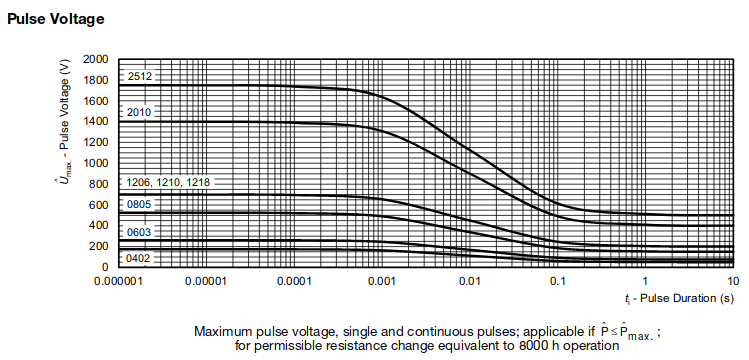

Policies usually go hand-in-hand with significantly increased voltages. These voltages can “jump” over the component, thereby causing significant damage downstream. Avoiding this is best done by staying below the highest voltage limits, which Vishay specifies as shown in figure 2.

Voltage resistance also depends on the duration of the spike

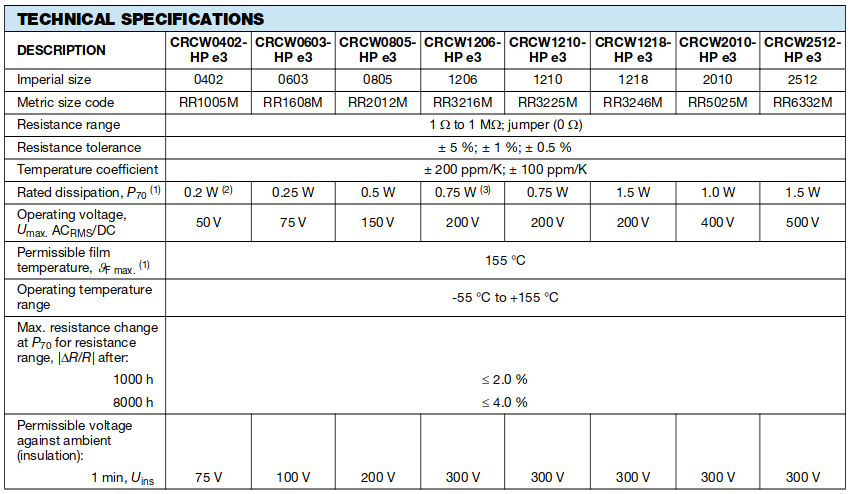

One particularly interesting aspect of the CRCW-HP e3 family is the availability of various case sizes. Our table shows but a few of the possible candidates, each of which has a different maximum thermal capacity.

Case size influences component robustness

While this might be surprising to beginners, the phenomenon can be explained easily. Keep in mind that thermal resistance is a function of the thermal mass of the part in question – if more ceramics are used, it is only logical that the component becomes more robust.